EXTENDING THE ORGANIZATION-

SUPPLY CHAIN MANAGEMENT (SCM)

SUPPLY CHAIN MANAGEMENT

- The average company spends nearly half of every dollar that it earns on production

- In the past,companies focused primarily on manufacturing and quality improvements to influence their supply chains

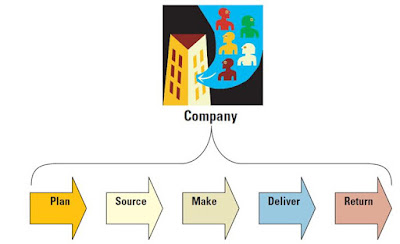

➽ The supply chain has 3 main links :

- Materials flow from suppliers and their "upstream" suppliers at all levels

- Transformation of materials into semi finished and finished products through the organization's own production process

- Distribution of products to customers and their "downstream" customers at all levels

INFORMATION TECHNOLOGY'S ROLE IN THE SUPPLY CHAIN

- IT's primary role is to create integrations or tight process and information linkages between functions within a firm

- FACTORS DRIVING SCM

VISIBILITY

- Supply chain visibility - the ability to view all areas up and down the supply chain

- Bullwhip effect - occurs when distorted product demand information passes from one entity to the next throughout the supply chain

CONSUMER BEHAVIOR

- Companies can respond faster and more effectively to consumer demands through supply chain enhances

- Demand planning software - generates demand forecasts using statistical tools and forecasting techniques

COMPETITION

- Supply chain planning (SCP) software - uses advanced mathematical algorithms to improve the flow and efficiency of the supply chain

- Supply chain execution (SCE) software - automates the different steps and stages of the supply chain

- SCP and SCE in the supply chain

SPEED

- 3 factors fostering speed

SUPPLY CHAIN MANAGEMENT SUCCESS FACTORS

- SCM industry best practices include :

🔻 Wean employees off traditional business practices

🔻 Ensure the SCM system supports the organizational goals

🔻 Deploy in incremental phases and measure and communicate success

🔻 Be future oriented

SCM SUCCESS STORIES

- Top reasons why more and more executives are turning to SCM to manage their extended enterprises

- Numerous decision support systems (DSSs) are being built to assist decision makers in the design and operation of integrated supply chains

- DSSs allow managers to examine performance and relationships over the supply chain and among : * Suppliers * Manufacturers * Distributors * Other factors that optimize supply chain performance

No comments:

Post a Comment